Wie alles begann

Seit frühester Jugend habe ich Modellschiffe gebaut. Funktionen waren mir dabei wichtiger als perfektes Aussehen.

Später kamen Schiffe mit Dampfmaschinen dazu.

Mit meinem Sohn zusammen verlagerte sich das Interesse irgendwann mehr auf die Gartenbahn.

2021 hatte ich (inzwischen Besitzer eines einfachen 3D- Druckers) dann die Idee wieder einmal ein Dampfschiff zu bauen.

Um die aufwendige Umsteuerungstechnik der Dampfmaschine zu vermeiden wollte ich eine Schubumkehr- Lösung realisieren.

Durch meine Arbeit bei Airbus kannte ich so etwas. Der mögiche Schub In Stellung Rückwärts von etwas unter 50%

schien mir ausreichend. Außerdem sollte ein einfaches unauffälliges Bugstrahlruder eingebaut werden,

damit das Schiff auf kleinen Gewässern klar kommt. Das sollte aber nicht das historische Aussehen stören.

Ich zeichnete eine Art Schaufelrad das hoffentlich ein bischen seitlichen Schub erzeugen sollte und sonst unsichtbar unter dem Rumpf

verborgen war.

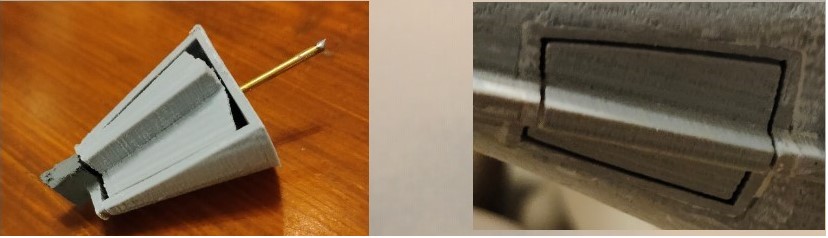

Die Realisierung von Schubumkehr- Ruder und Bugstrahlruder war mit dem 3D- Drucker recht einfach.

Die Leistungen von diesen beiden Bauteilen übertrafen später meine Erwartungen bei weitem und führten zu weiteren Untersuchungen.

Der einfache Bugstrahler

Es ist ein Schaufelrad mit der Achse in Richtung Schiffs- Längsachse, 11 Grad aufwärts geneigt, für den Motor- Anschluß.

Ablegen mit dem Bugstrahler

Wie man sieht funktioniert das ganz gut. Aber: warum?

Die Theorie hinter derartigen Schaufelrädern

Schubumkehr- Ruder

Er besteht aus zwei Hälften die parallel stehen wenn sie als Ruder arbeiten

Für Rückwärts schließen die beiden Hälften:

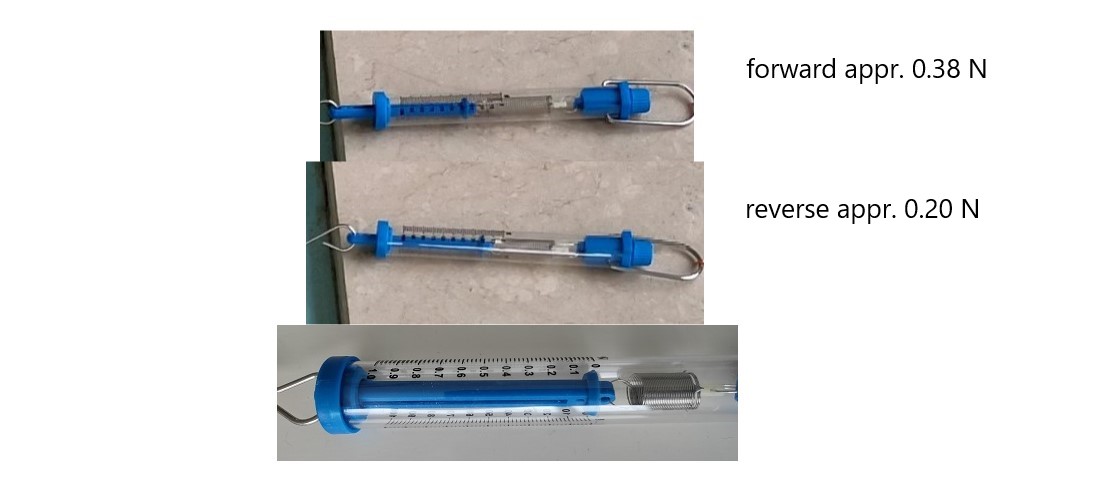

Bei modernen Flugzeugen hat ein Schubumkehrer eine Wirksamkeit von 40 bis 45 % des Vorwärtsschubs.

Hier eine Messung bei meinem Schiff "ERIKA":

Das bedeutet: ca. 53 % bei Rückwärts. Nicht schlecht!